Products » Turn Key Project Supply » Frozen Store & IQF Project

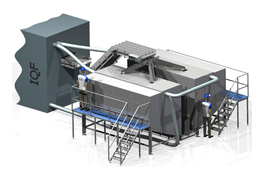

IQF is a food preservation technology where fresh food passes through the low temperature zone very quickly, leaving very low and safe microbial counts. This type of freezing results in the product free rolling and not clotting into lumps. Through the IQF process it is possible to offer fresh picked' flavors (fruit, vegetable, sea foods, meat, and other fresh foods) all year round, in packaging convenient for the busy consumer. IQF foods lock in the essential nutrients and flavor, with optimum color, taste and texture. The appeal of IQF foods is that it closely resembles the much-sought-after appearance, flavor and nutrition of the fresh versions. The project envisages installing a 2000 kg per hour IQF Line capable of handling a variety of products. The suggested system for achieving the sub zero temperature temperatures is ammonia liquid pumping system. The major produces which will be processed in the IQF are green peas, mixed vegetables, sweet corn and other vegetables and fruits.

This is quite evident from the product basket of some of the prominent retailers like Big Bazar, Fair Price, Giant, etc. Though the product basket for the frozen fruits and vegetables varies slightly across the Globe, however there are certain products which are commonly popular. These products are:

- Frozen Potatoes – Solid form, French Fries form and Wedges form.

- Frozen Cauliflower

- Frozen Broccoli

- Frozen Beans

- Frozen Peas

- Frozen Mushrooms

- Frozen Spinach

- Frozen Corn

- Frozen Cut Vegetables – Concoction of above mentioned vegetables

Frozen Fruits and Vegetables

IQF Processing of Green Peas